The Complicated Reality of N95 Mask Shortages

While mask mandates are hotly debated for the general population, medical facilities have relied on effective personal protective equipment since before this pandemic. Clearly, masks are effective at protecting people from spreading and contracting COVID-19. However, ongoing reports suggest that N95 masks are still in short supply. SPH Medical has a full stock of N95 masks ready for protecting healthcare workers during the Covid-19 pandemic.

Doctors talk about wearing the same protective gear for multiple days. Some workers have attempted to clean their N95 masks in a futile attempt to prolong their lifespan. Workers in other essential settings sometimes have to settle for less effective protective equipment since it is impossible to secure a N95 mask for daily use.

This is deeply problematic for the safety of America’s frontline workers. A NIOSH N95 mask is designed to filter out nearly all airborne particles. Model 9500-N95 masks from Makrtie and other N95 masks are tested to prevent the transmission of fluids, other respiratory droplets and aerosols. There is simply no product out there that can offer protection like the N95 mask.

Unfortunately, even with six months to build up the national supply, reports suggest that shortages exist and may continue to persist into 2021.

The problem is multifaceted. Despite the fact that six months have elapsed, there has been limited coordinated effort from the government to shore up the production process. Manufacturing output is not a short-term operation. It must be planned and financed accordingly. Without proper preparations or investments, manufacturers have been hindered on a number of fronts in their production of the coveted NIOSH N95 mask that are used for protecting healthcare workers and the general pubic.

N95 Mask Shortage

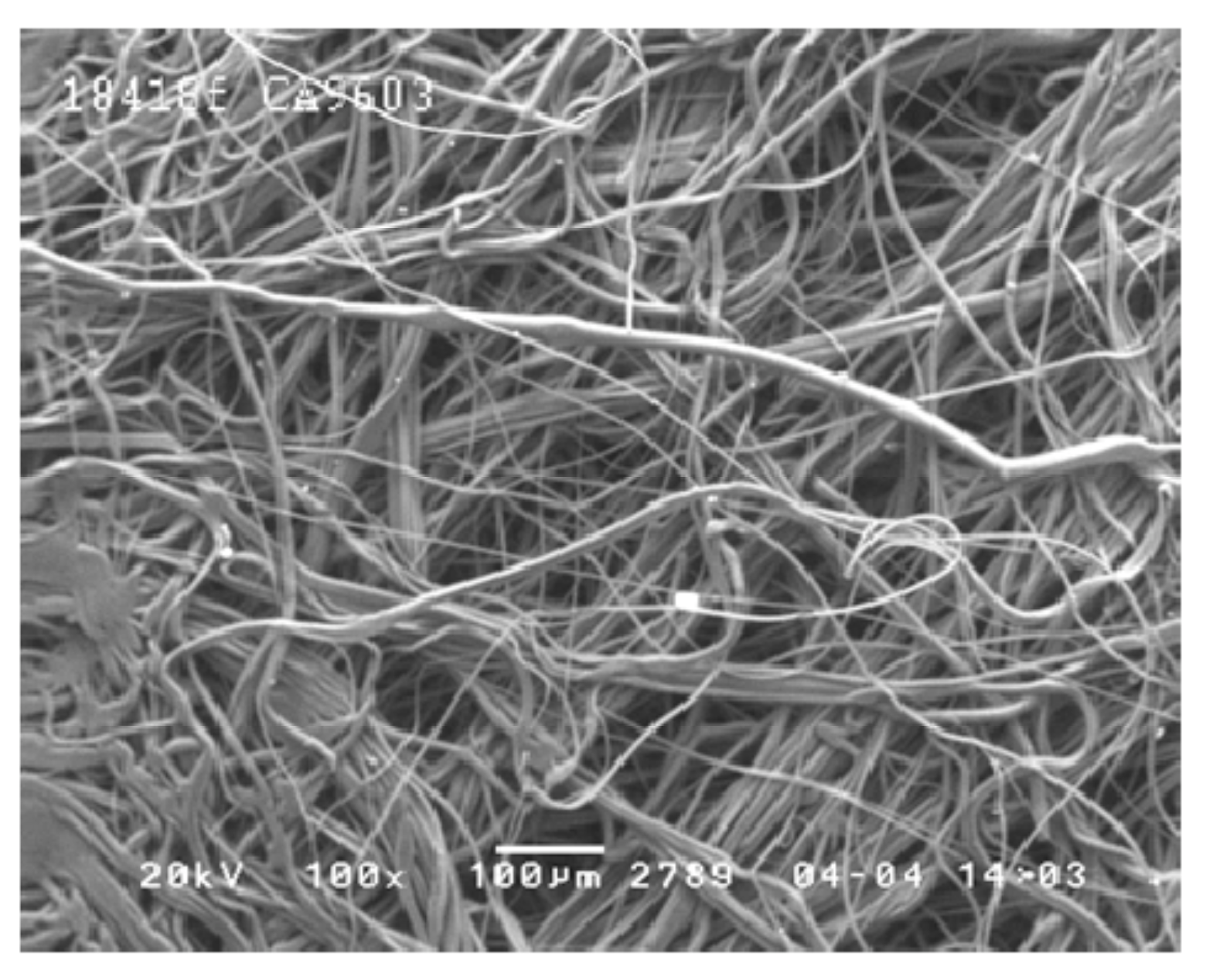

In particular, current shortages can be linked to a lack of raw materials. In order to make an effective N95 mask, manufacturers need access to meltblown textile. Meltblown textile is a key component in mask manufacturing. Without sufficient supply of this textile, there is simply no way to increase the output of masks.

The largest supplier of meltblown fabric in the United States is Berry Global. This company is located in Evansville, Illinois, and it has an annual revenue of $2.7 billion. The top competition comes from Kimberly-Clark in Georgia and Dupont in Delaware, but both of these companies produce significantly less. Despite high production yields from these companies, much of their product is shipped overseas. In particular, reports suggest that 40 percent of the American production load of meltblown fabric went to Pakistan this fall.

Without meltblown textile staying in the American market, mask manufacturers have a limited ability to increase their production as needed. Moreover, some manufacturers are skittish to make the necessary investment for the national supply. In order to increase production, these manufacturers have to make a significant investment. It requires diverting funds and facilities from other manufacturing projects. In other words, manufacturers have to give up on other profitable sectors without any promise of long-term growth.

After all, many manufacturers have learned the hard way that short-term needs do not always yield long-term changes. During the Swine Flu pandemic in 2009, the demand for masks also skyrocketed. However, once the disease was under control, the demand plummeted quickly. This left manufacturers in a lurch, and it left their profit margins very vulnerable.

Exporting Significant Amounts of the American Supply

There are reasons for manufacturers to face similar hesitations today. Although the government has made dramatic orders for masks, there are no long-term purchase guarantees included. For example, companies like Honeywell and 3M received $134.5 million for increased production. However, meltblown textile was unrestricted. This meant that manufacturers still exported significant amounts of the American supply, and without a coordinated approach, there has been no way to track exactly how much is available at any given time.

Fortunately, some companies are tackling the challenge. The Makrite N95 mask is an excellent source of protection. With 30 years of experience, Makrite knows what it takes to provide protection. As the company moves to counteract the growing demand and stymied national stockpiles, it is more important than ever to work with authorized distributors like SPH Medical. When you choose SPH Medical, you can be confident that the model 9500-N95 masks you receive are viable and of the highest quality for protecting healthcare workers and the public. Moreover, the supply chain can be expedited to save you time and money. This ensures that every healthcare worker can be protected with a Makrite N95 mask.

Contact SPH Medical to discuss your specific needs and establish a continuous supply of NIOSH Certified N95 masks and other essential supplies.